What is glycol chiller?

Glycol water chiller is a kind of cooling equipment specially used in industrial field, as the name suggests, glycol water chiller adopts glycol as the cooling medium of this equipment, glycol water chiller mainly consists of circulatory system, compressor, condenser, evaporator, and other components, this equipment can achieve the absorption and discharge of heat generated by all kinds of equipments or processes, in order to maintain the temperature of equipments or processes in the setting range Glycol chiller is widely used in pharmaceutical, food processing and other industries to provide continuous and stable cooling solutions for industrial production.

What type of tubing for glycol chiller?

Glycol Chiller piping is an important location for the transmission of cooling medium and transfer of cooling effect, usually using stainless steel piping with strong corrosion resistance, even after long-term use will not be corroded by ethylene glycol, and at the same time have good strength and pressure resistance, can withstand the pressure generated in the process of ethylene glycol cooling, suitable for a variety of industrial environments.

What are the benefits of glycol refrigeration?

Why glycol is used in chiller? Ethylene glycol is a kind of glycol with excellent heat transfer performance, can efficiently absorb and release heat, provide stable cooling effect for equipment and space; and ethylene glycol has high anti-freezing ability, its own has a low freezing point, usually between -13℃ and -16℃, can be maintained in a liquid state at low temperatures, to avoid the problem of icing of the cooling system at low temperatures, which is also ethylene glycol can be used as a cooling medium This is also an important factor that ethylene glycol can be used as a cooling medium.

What does a glycol chiller do?

Glycol chiller can meet the cooling needs of industrial production process, play a cooling effect on the production equipment and production process, improve the production capacity of the equipment and extend the service life of the equipment; for the larger plant or space, the chiller produces cold water through the glycol cooling medium, and passes the cold water through the circulating system to the air-conditioning equipment of the plant, so as to realise the effect of air-conditioning refrigeration and temperature control.

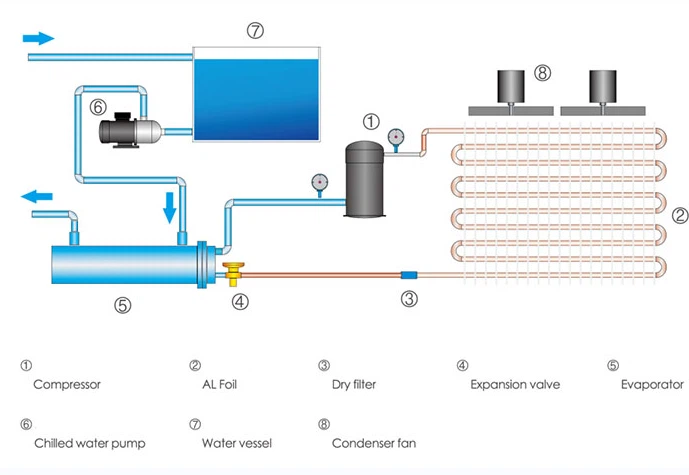

Glycol chiller working principle

How does a glycol chiller work? The working principle of glycol chiller is mainly based on the principle of evaporative cooling, the conversion from high temperature and high pressure gas to low pressure and low temperature liquid, through the continuous circulation flow, to achieve the cooling effect on the equipment or process.

● Compressor: Firstly, the glycol is compressed into high temperature and high pressure gas by compressor.

● Condenser: The compressed high-temperature and high-pressure gas of ethylene glycol is dissipated through the condenser and turns into a high-pressure liquid.

● Expansion Valve: The high pressure liquid is expanded through the expansion valve to reduce the pressure and temperature.

● Evaporator: The low-temperature, low-pressure liquid evaporates in the evaporator, absorbing heat and lowering the temperature.

What is a glycol chiller used for?

● Pharmaceutical industry: cooling reaction tanks, controlling constant temperature in the pharmaceutical process, ensuring product quality.

● Food processing industry: to cool food processing equipment, maintain food freshness, and handle at a specific temperature.

● Plastic manufacturing industry: used to cool injection moulding machines, reduce the temperature of plastic moulding.

● Electronics industry: cooling semiconductor equipment, temperature control in the manufacturing process of electronic components.

● Building industry: Used in central air-conditioning systems for large buildings to provide cooling effects in the space.

● Brewing industry: control of fermentation temperature during the brewing process, temperature control of wine cellars, and temperature control of wine production equipment.

How to add glycol to a chiller?

1. Confirm the type of glycol: There are different types and use levels of glycol. Before injecting glycol into a glycol chiller, you need to make sure that you select the appropriate type and specification of glycol.

2. Determine Glycol Capacity: Depending on the equipment and design, determine the capacity of glycol to be injected.

3. Switch off the chiller and disconnect the power supply: Remember that before any maintenance or operation, you need to ensure that the glycol chiller has been completely switched off and disconnected from the power supply to ensure safety.

4. Locate the glycol injection port: Glycol chillers usually have a dedicated injection port, usually located on the side or top of the unit and labelled accordingly (this may vary slightly between glycol chiller manufacturers)

5. Prepare the injection tool: Prepare a vessel to hold the glycol and prepare the injection tool, e.g. syringe, funnel or pump.

6. Seal the injection port: After completing the injection, the injection port needs to be cleaned to ensure that no glycol remains and sealed with a cap or sealing plug to prevent glycol leakage.

Please note that ethylene glycol is a toxic substance and the operation process must comply with the relevant safety regulations. If you are not quite sure how to add ethylene glycol or if you have any questions, you can consult the manufacturer of the ethylene glycol chiller or a professional for advice.

How often to clean glycol chiller?

The cleaning frequency of glycol chillers depends on a number of factors, mainly based on the use of the environment, the use of time and other conditions; in general the cleaning frequency of glycol chillers is recommended every 3 to 6 months for a thorough cleaning, if the use of harsh environments, poor water quality, or equipment for a long period of time, you may need to clean more frequently.

How to clean glycol chiller? Because glycol chillers have a different cooling medium than ordinary chillers, you need to focus on emptying the glycol in the cooling circuit to completely remove the glycol from the system, and more cleaning and maintenance content does not differ from ordinary chillers, So, if you need more details about chiller cleaning and maintenance, you can go through the"Industrial Chiller Maintenance Checklist".